Gbawara agbawa na derusting usoro nke ígwè oghere etiti

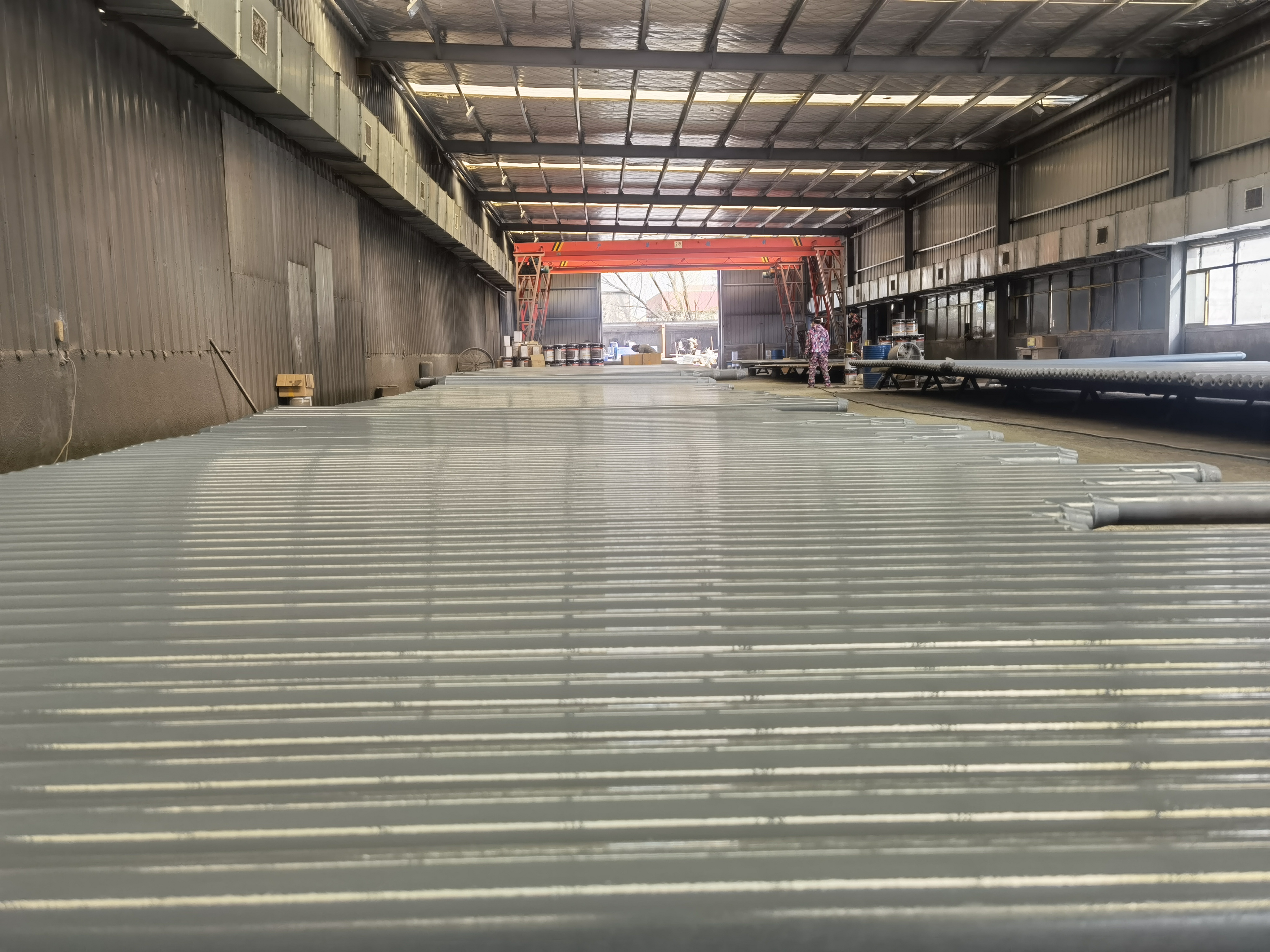

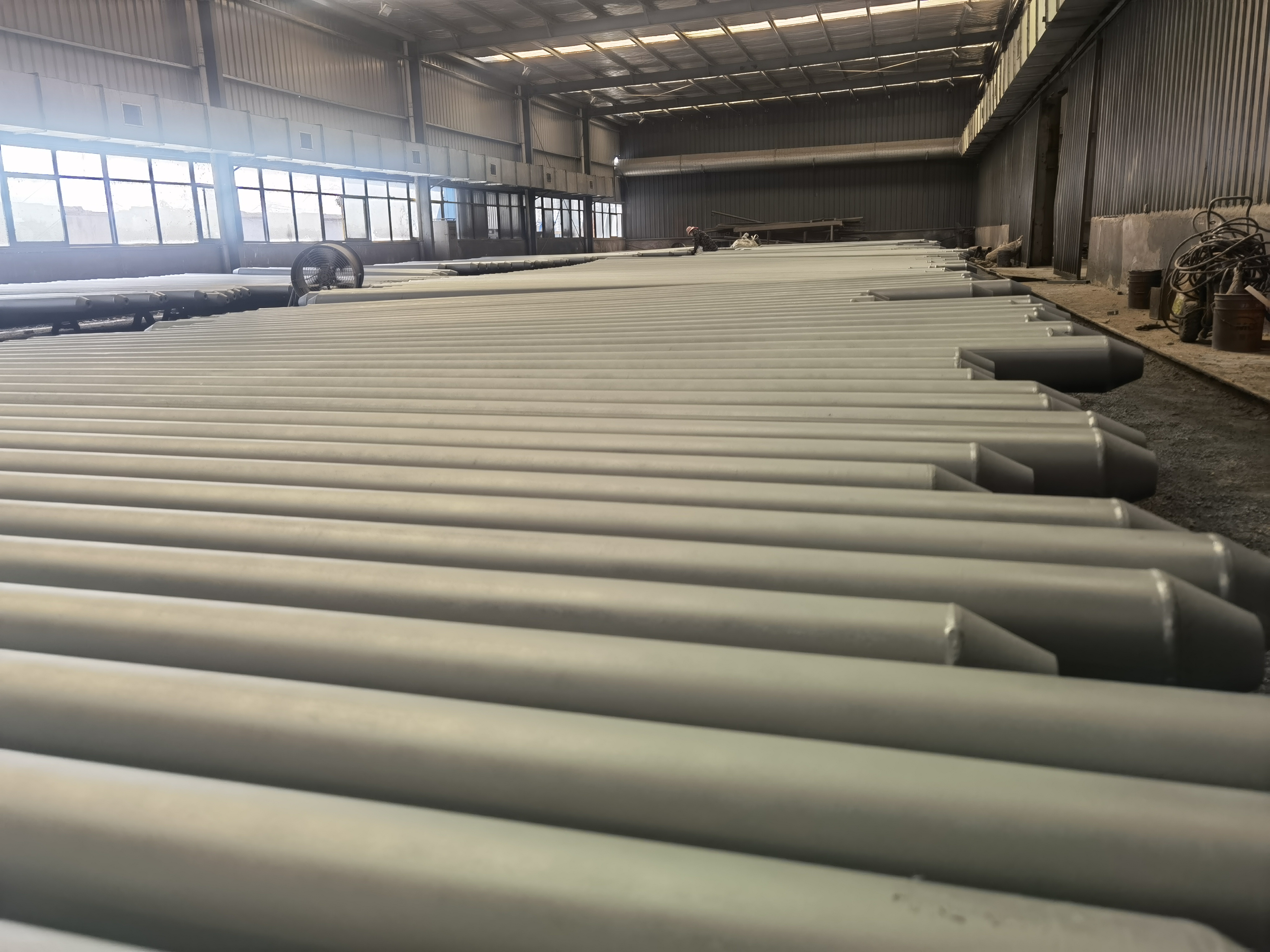

Mgbawa agbawa:

Mgbawa agbawa agbawa agbawa bụ iji ike centrifugal nke impeller na igwe ogbugba ogbunigwe mgbe ọ na-agbagharị n'ọsọ dị elu, na usoro ịgbawa egbe dị oke elu.

A na-agbapụ ọsọ ọsọ nke ígwè ahụ n'elu ígwè a ga-agwọ ya, na-eme ka ọ bụrụ ihe na-egbuke egbuke ma na-egweri, na-ewepụkwa ọnụ ọgụgụ oxide n'elu ígwè ahụ.

na nchara, ma na-emepụta ụfọdụ ihe siri ike.Mgbawa agbawa na-arụ ọrụ nke ukwuu ma enwere ike ịme ya na ebe ejiri akara.

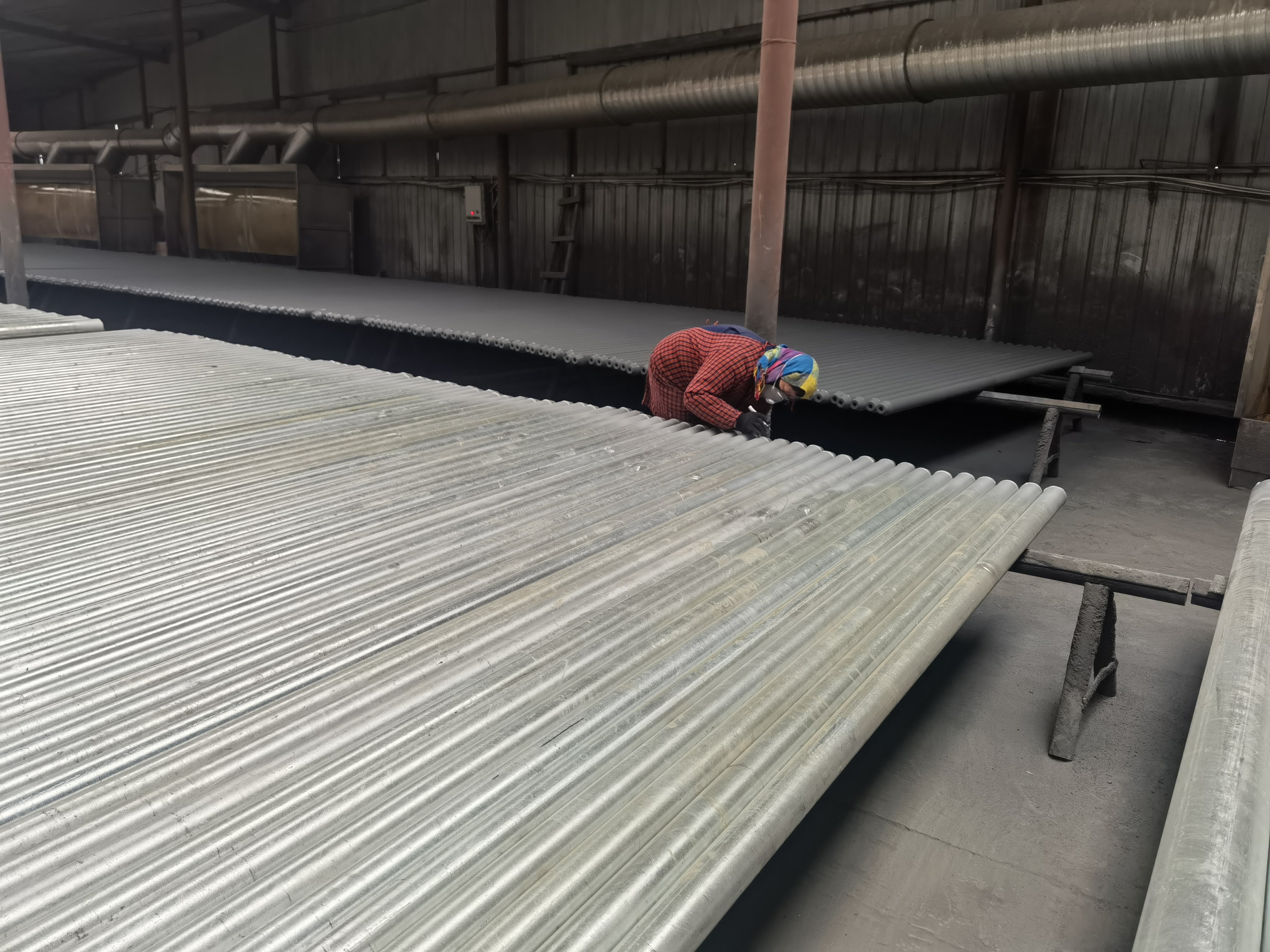

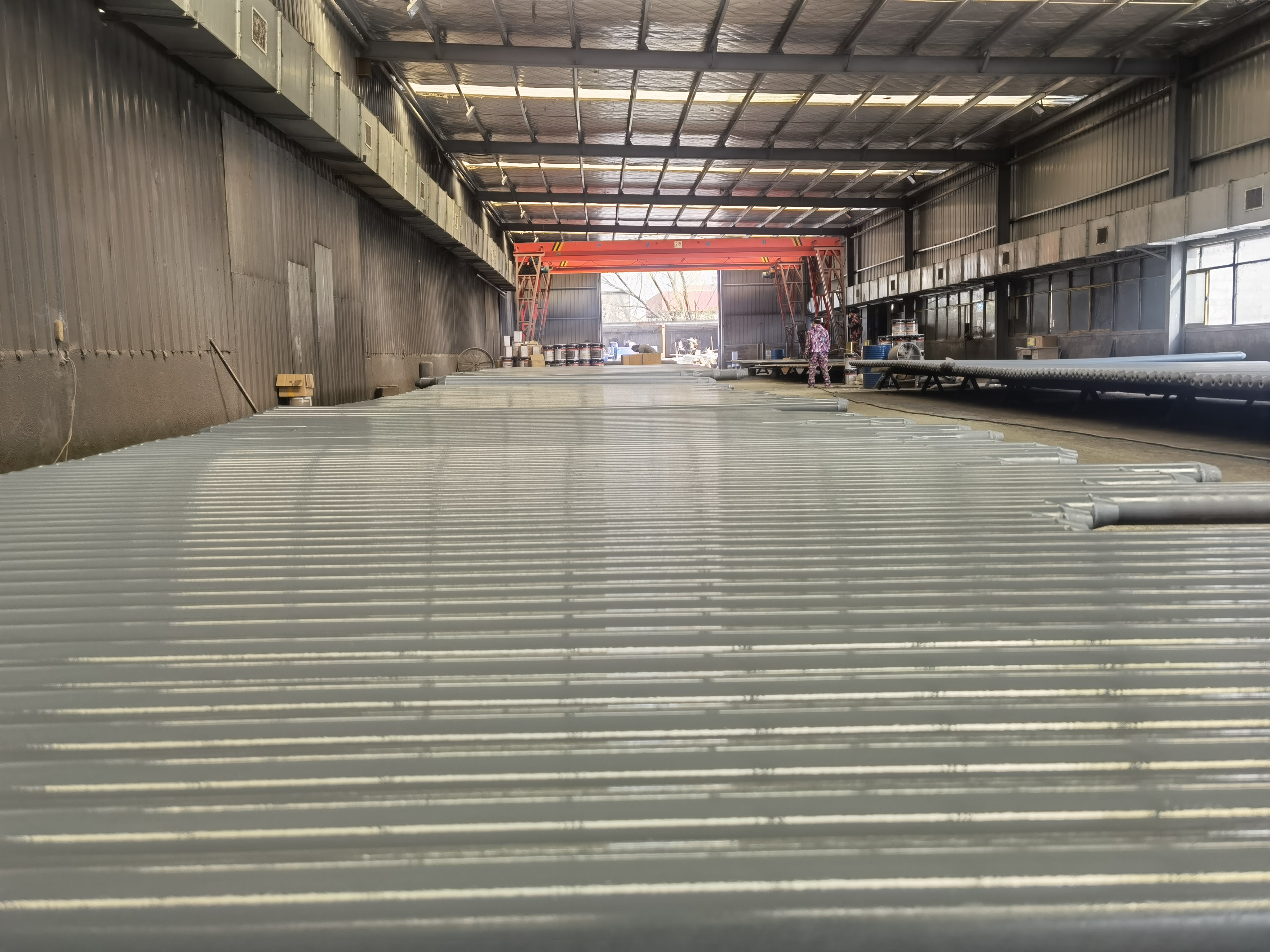

Ọkwa mgbawa agbawa na nchara nchara;

(1) Obere ogbunigwe gbawara na iwepụ nchara.Igwe nchara kwesịrị ịbụ nke a na-ahụ anya na griiz ma ọ bụ unyi na enweghị ike oxide dị ike, nchara na mkpuchi agba na mgbakwunye ndị ọzọ;

(2) Nchara nke ọma na mkpochapụ nchara.Igwe nchara kwesịrị ịbụ nke a na-ahụ anya na griiz ma ọ bụ unyi na enweghị ike oxide dị ike, nchara na mkpuchi agba na mgbakwunye ndị ọzọ;

(3) Mgbochi gbawara agbawa na mkpochapụ nchara.Igwe nchara kwesịrị ịbụ nke a na-ahụ anya griiz ma ọ bụ unyi, ọnụ ọgụgụ, ihe mgbakwunye ígwè dị ka nchara na mkpuchi agba, ihe ọ bụla fọdụrụnụ kwesịrị ịbụ naanị ntakịrị ntụpọ n'ụdị ntụpọ ma ọ bụ ibe;

(4) Mgbawa agbawa na mwepụ nchara iji mee ka elu igwe dị ọcha.Ngwongwo nchara kwesịrị ịbụ nke a na-ahụ anya griiz ma ọ bụ unyi, akpụkpọ anụ oxidation, nchara na mkpuchi agba na ihe mgbakwunye ndị ọzọ, na-egosi otu luster dara;