Usoro ịgbado ọkụ nke oghere oghere ígwè

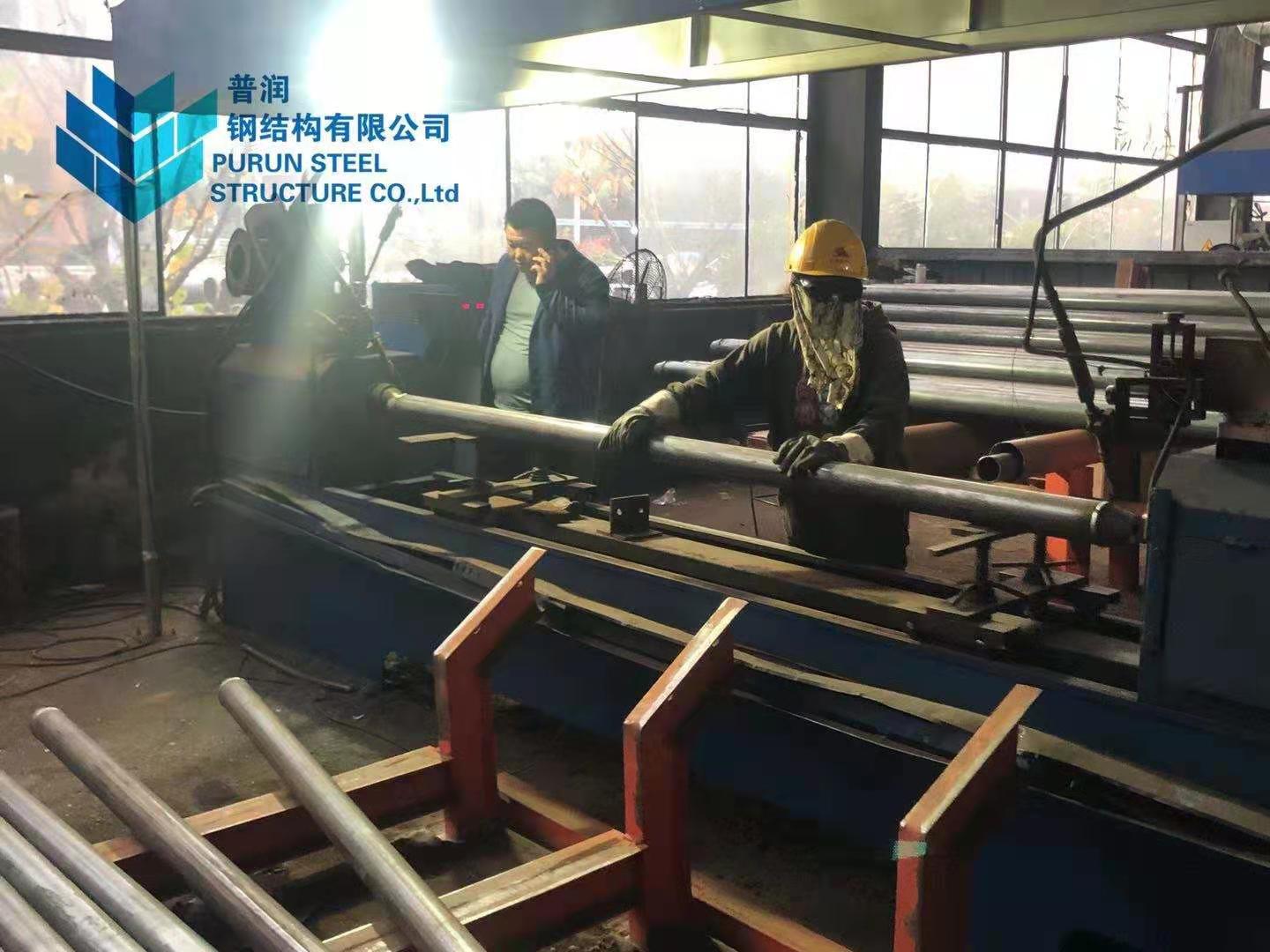

ịgbado ọkụ:

Usoro ịgbado ọkụ bụ usoro dị mkpa na mmepụta nke oghere oghere ígwè, a ghaghị ime ya n'ụzọ siri ike dịka ntuziaka ọrụ ịgbado ọkụ.Wetulata nchekasị fọdụrụnụ nke ịgbado ọkụ na-akpata, ma dozie nrụrụ ahụ n'oge site na ikpo ọkụ ọkụ.

A. Mgbe ígwè ọkpọkọ na-welded na akara akara na ígwè ọkpọkọ, a ga-emeghe oghere dị ka ihe ndị a chọrọ, na oghere n'akuku ga-ezute ihe ndị a chọrọ n'akuku nke e guzobere n'etiti electrode na uzo elu iji zere unfusion na slag nsonye.Tụkwasị na nke ahụ, oghere oghere kwesịrị ịdị ukwuu nke mere na arc electrode nwere ike iru ala nke oghere ahụ ma zere omimi ntinye ezughị ezu.

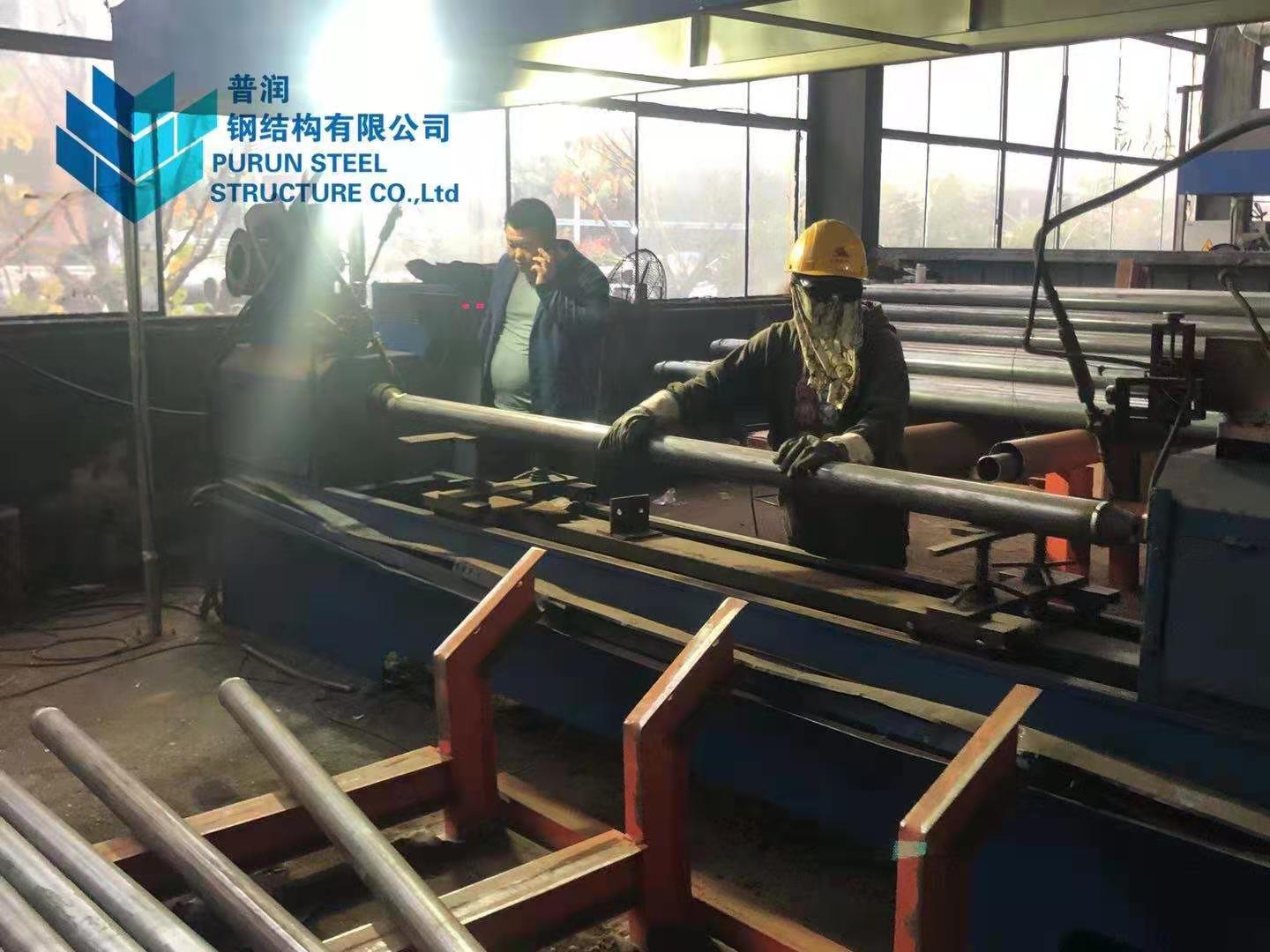

B. Zere ịtọ eriri ịgbado ọkụ n'etiti mkpanaka ahụ mgbe a na-agbanye ọkpọkọ ígwè.

C. Ihe ndị chọrọ nlebara anya na ọrụ ịgbado ọkụ:

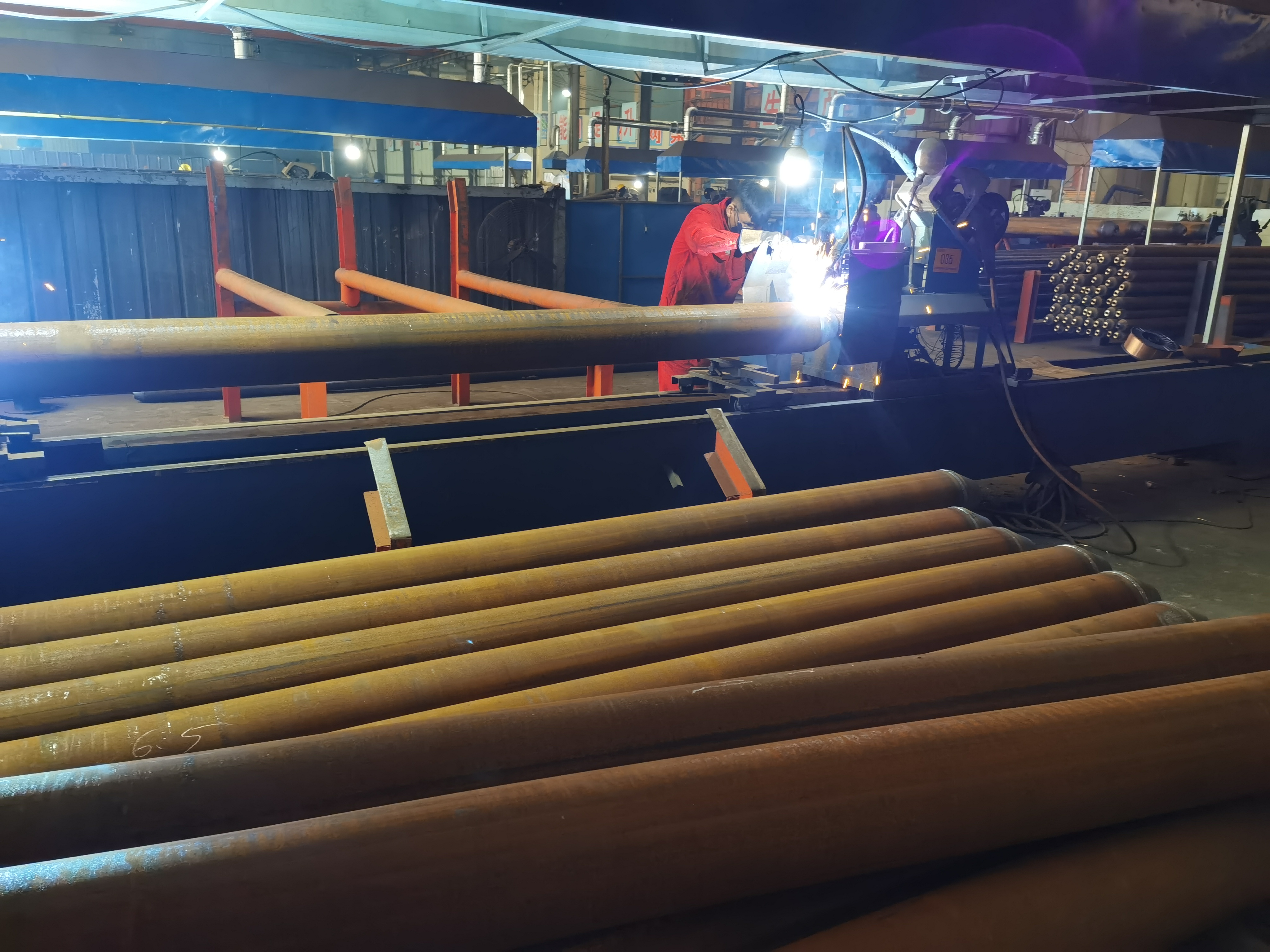

a.N'oge ịgbado ọkụ nke akwụkwọ ntuziaka, oke mbufe ekwesịghị ibu oke, a na-eji ịgbado ọkụ ọtụtụ ngafe na akwa akwa.

N'oge usoro ahụ, a ga-ewepụcha weld bead ma ọ bụ interlayer welding slag, slag inclusion, oxide, wdg.Enwere ike iji igwe na-egweri ihe, ígwè.

Ngwa dị ka brushes waya.

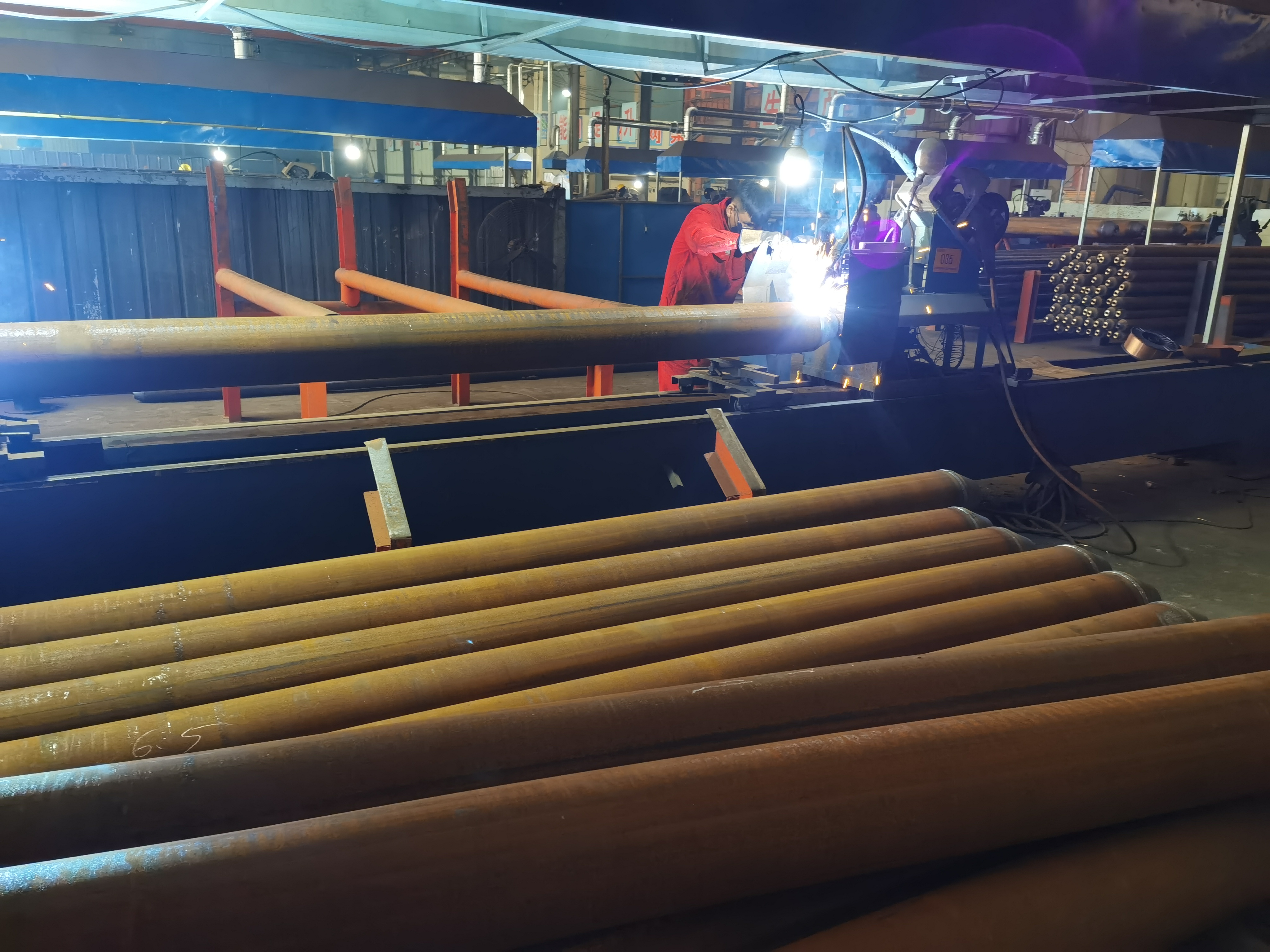

b.Otu eriri ịgbado ọkụ kwesịrị ka a na-agbakọ ya mgbe niile ma wuchaa ya n'otu oge.

c.Maka nkwonkwo weld dị iche iche, mgbe emechara ịgbado ọkụ ahụ, a ga-ehichapụ slag na spatter metal n'elu nke weld.

Lelee ịdịmma nke weld ahụ, na enweghị nkụda mmụọ, weld bead, undercut, blowhole, enweghị ngwakọta, mgbape.

na ntụpọ ndị ọzọ dị.

d.Mgbe weld butt welded, a ga-eme nchọpụta ntụpọ ultrasonic mgbe awa 24 gachara.