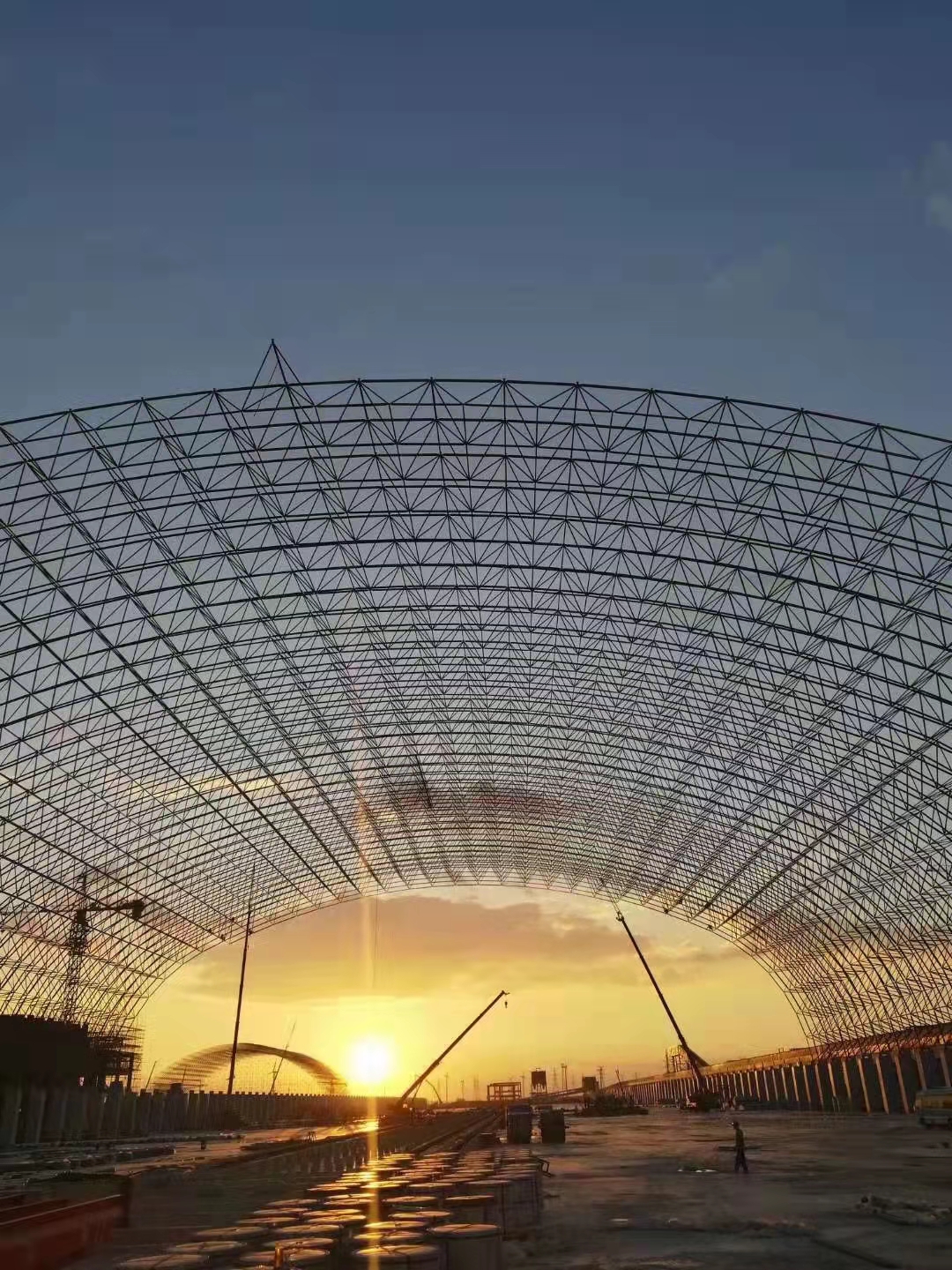

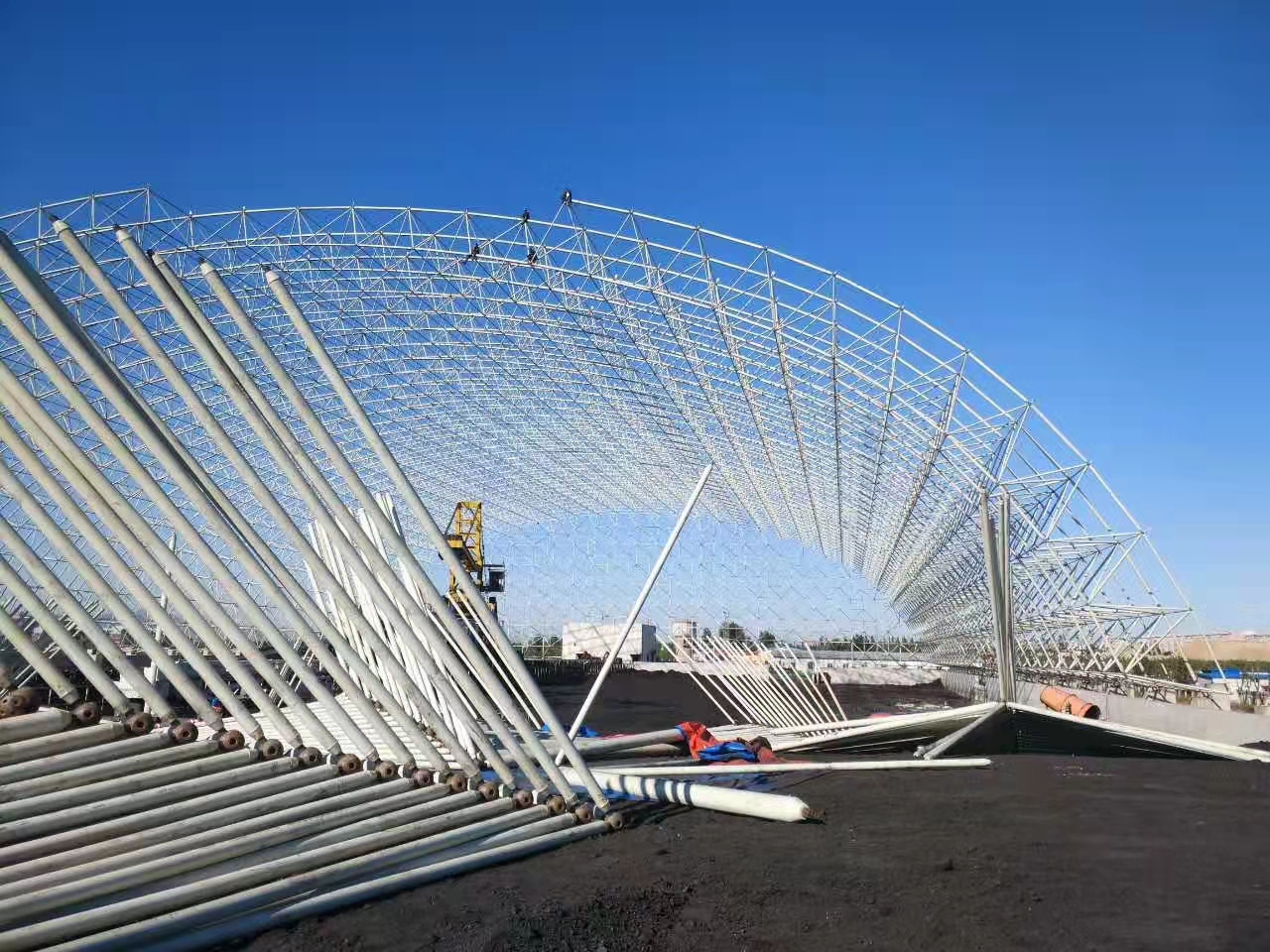

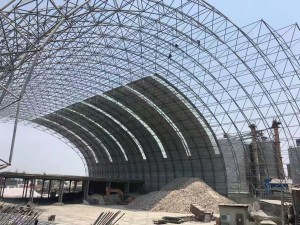

Ordos thermal ike osisi ọkara okirikiri ígwè Ọdịdị oghere etiti

Raw material Q235B welded pipe / Ngụkọta elu bụ 49 mita / ngụkọta ogologo bụ 96 mita / ngụkọta ogologo bụ 567 mita.

1. Nhọrọ ihe kwesịrị ịdabere na asambodo ịdị mma nke ezi uche na akụkọ nyocha ọzọ, kwekọrọ n'ụkpụrụ mba dị ugbu a.

2. The ígwè ọkpọkọ adopts Q355B ígwè, enweghị nkebi ígwè ọkpọkọ ma ọ bụ elu ugboro welded pipe (GB / T 700).

3. A na-eme bolts dị elu nke 40Cr na-emenyụ ma na-ekpo ọkụ ma na-ekpo ọkụ dị ka "Ọnọdụ Nkà na Ụzụ maka Ọdịdị Igwe Igwe Igwe Ọdụdọ Dị Elu" GB / T 16939. Ọrụ nke dayameta.

4. Nchara bọọlụ na-mere nke No. 45 ígwè forgings nke kwekọrọ na "Technical Ọnọdụ maka High-Quality Carbon Structural Steel" GB 699, na a mkpụrụ ike nke 360N / mm2.

5. A na-eji ígwè Q355B na-ekpuchi efere mkpuchi nke isi cone, na isi cone bụ nke forgings.

6. The threadless nut mere nke Q355B ígwè forgings.Mgbe dayameta nke bolts dị elu dị> M30, jiri igwe nchara 45 mee ihe.

7. A na-eji 40Cr na-eme ka ihe nkedo na-ejikọta ya na-emenyụ na ọkụ.

8. A na-eji ígwè Q355B na-akwado nkwado ahụ, na nkwado nke Q235B ígwè

9. The electrode adopts E43XX usoro;Usoro E50XX (maka ịgbado ọkụ nke bọọlụ bolt na ọgịrịga ibu)

10. The purlins na-mere nke Q235B C-ụdị ígwè.

11. Nkịtị bolts na-mere nke ọkwa C siri ike bolts mere nke Q235B ígwè na-emezu ihe ndị chọrọ nke ugbu a mba ọkọlọtọ, na arụmọrụ ọkwa bụ 4.8.

12. Ndị na-agbado ọkụ eletrik na wires eji maka ịgbado ọkụ kwesịrị izute mkpa chọrọ nke ugbu a mba ụkpụrụ.Ịgbado ọkụ n'etiti Q235B steels na-anabata E43 usoro electrodes, na ịgbado ọkụ n'etiti Q345B steels nakweere E50 usoro electrodes.

13. Ngwongwo ihe eji eme ihe: Hụ ihe osise grid n'elu ụlọ maka nkọwa.

14. Na mgbakwunye na imezu ihe achọrọ nkọwapụta ihe nke mba, igwe eji arụ ọrụ a kwesịkwara imezu ihe ndị a:

a) Ọnụ ọgụgụ nke ọnụ ahịa a tụrụ atụ nke ike mkpụrụ nke ígwè na ọnụ ahịa a tụrụ atụ nke ike nkwụsị ekwesịghị ịbụ ihe karịrị 0.85;

b) Nchara kwesịrị inwe usoro ntinye doro anya, na elongation kwesịrị ịdị ukwuu karịa 20%;

c) Nchara kwesịrị inwe ezigbo weldability na ruru eru mmetụta siri ike;